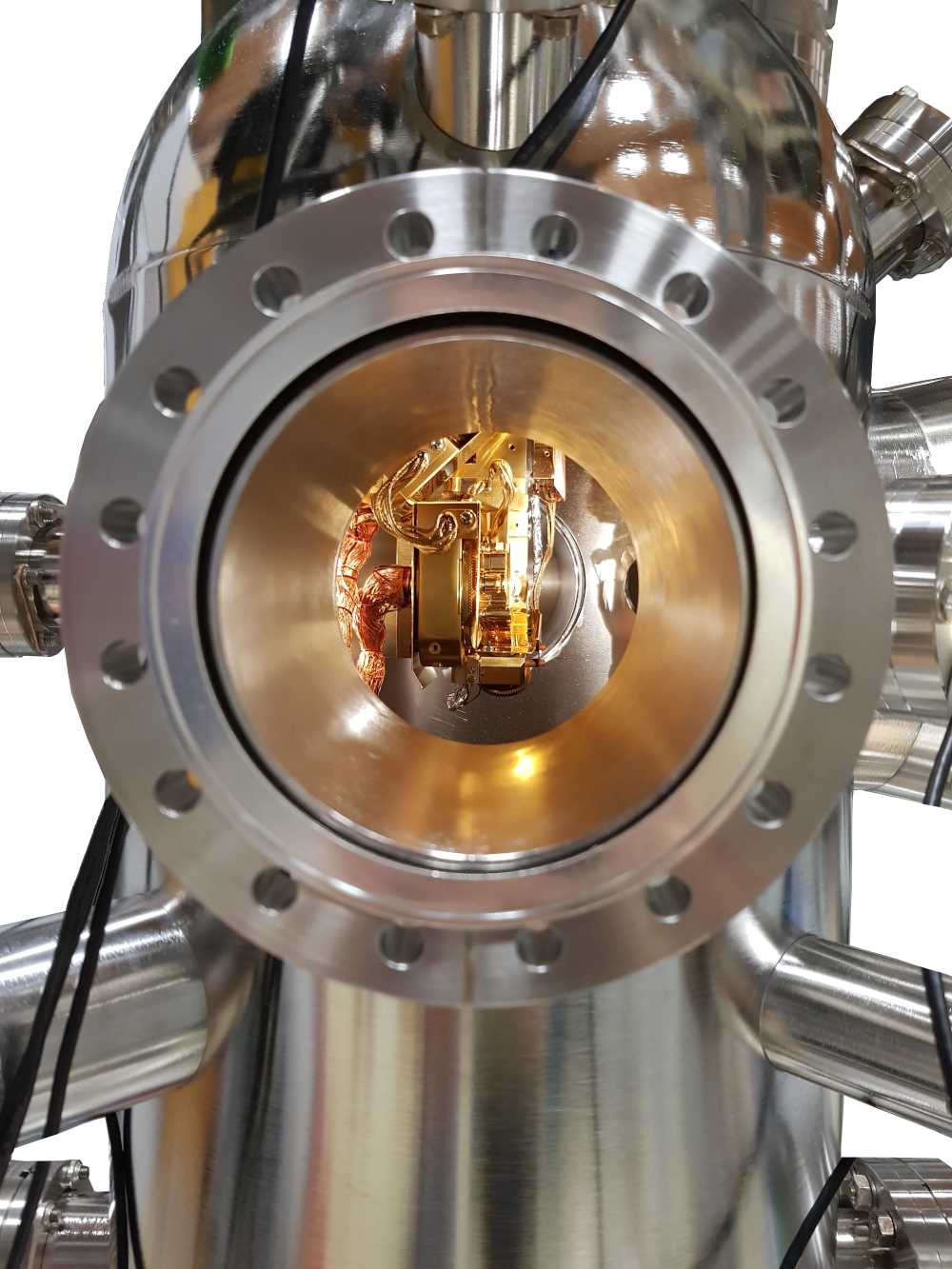

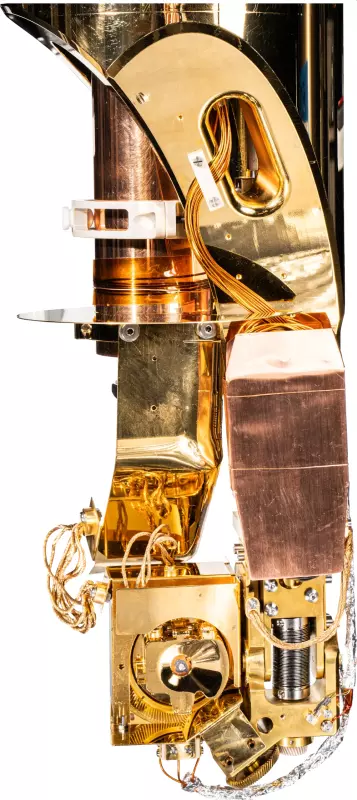

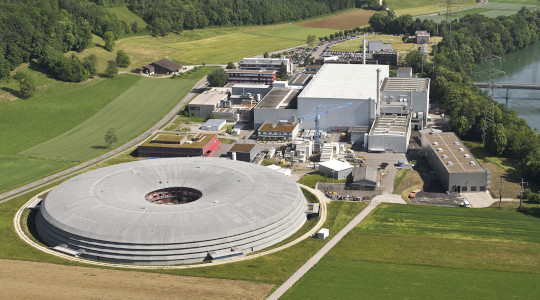

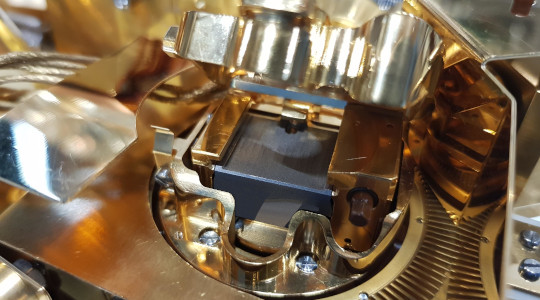

Designed for the Paul Scherrer Institute

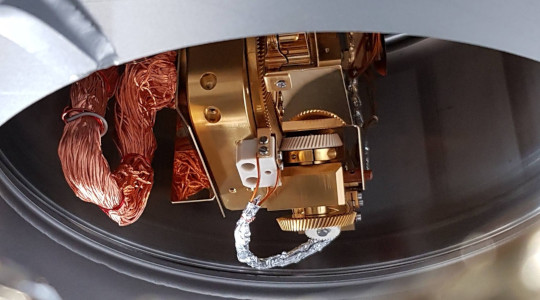

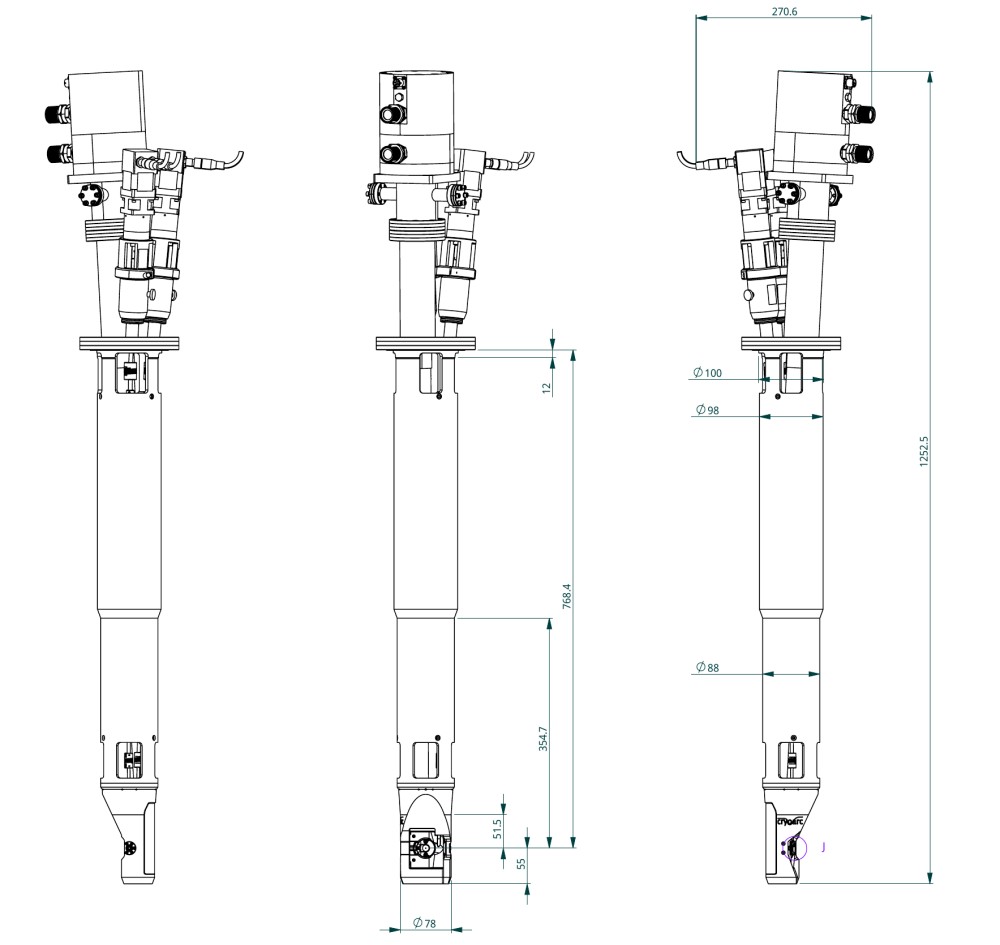

The manipulator was designed for the Surface / Interface Spectroscopy beamline at the Swiss Light Source and now elements are found at several other places in the SLS. In operation since December 2019, it provides a crucial part of enabling higher resolution and flexibility while being robust. This manipulator is now accessible to anyone requiring cold temperatures and flexibility simultaneously.